Mobile, AL — Construction continues on the $60 million development of the Port of Mobile’s rail-served roll-on/roll-off vehicle processing facility. The project, announced in the Spring of last year, is slated for completion by the end of 2019.

The southeastern U.S. has become a hotbed of automotive assembly plants in recent years, and the new “Southeast Automotive Gateway” at Mobile promises a shorter overland haul for existing assembly plants, including Honda, Hyundai and Mercedes in Alabama, Toyota in Mississippi, Volkswagen in Tennessee, and KIA in Georgia. Once complete, the terminal is expected to handle up to 160,000 import and export vehicles annually.

The southeastern U.S. has become a hotbed of automotive assembly plants in recent years, and the new “Southeast Automotive Gateway” at Mobile promises a shorter overland haul for existing assembly plants, including Honda, Hyundai and Mercedes in Alabama, Toyota in Mississippi, Volkswagen in Tennessee, and KIA in Georgia. Once complete, the terminal is expected to handle up to 160,000 import and export vehicles annually.

The port’s existing rail infrastructure positions it particularly well to take advantage of automotive and heavy cargo import/export opportunities in the future. Indeed, five Class I railroads (BNSF, CN, CSX, Kansas City Southern and Norfolk Southern) directly connect to the former 57-acre bulk facility on which the new roll-on/roll-off terminal is being built.

Alabama Port Authority CEO James Lyons highlighted the port’s rail advantage at the announcement, writing in a press release that the agreement, “represents a key step in diversifying the Port Authority’s business while providing a strategic asset to regional automotive shippers.”

Greg Canfield, secretary of the Alabama Department of Commerce, echoed this statement at the signing of the agreement, commenting, “This new facility is an important piece of infrastructure that will help our automakers maintain their competitive edge as they continue to grow.”

The facility, which is being built and operated by a division of Argentinian logistics firm Terminal Zarate, will poise Mobile to be the entry point of imports from South America as well. In addition to new cars and trucks, the facility will be able to handle new recreational vehicles, agricultural equipment, and movement of military vehicles.

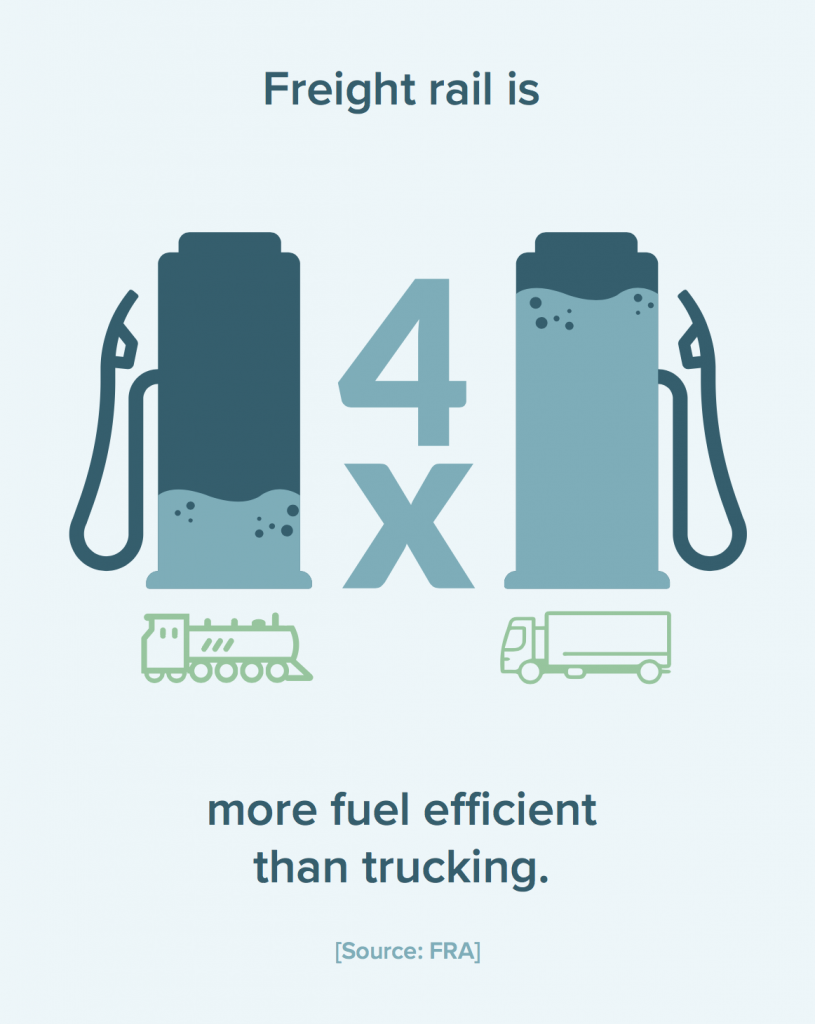

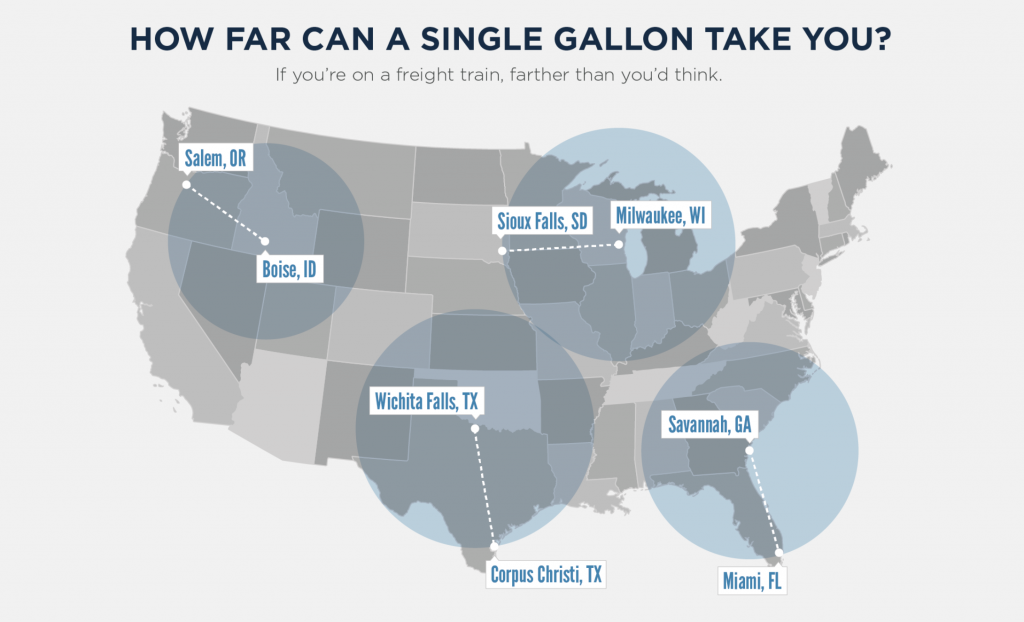

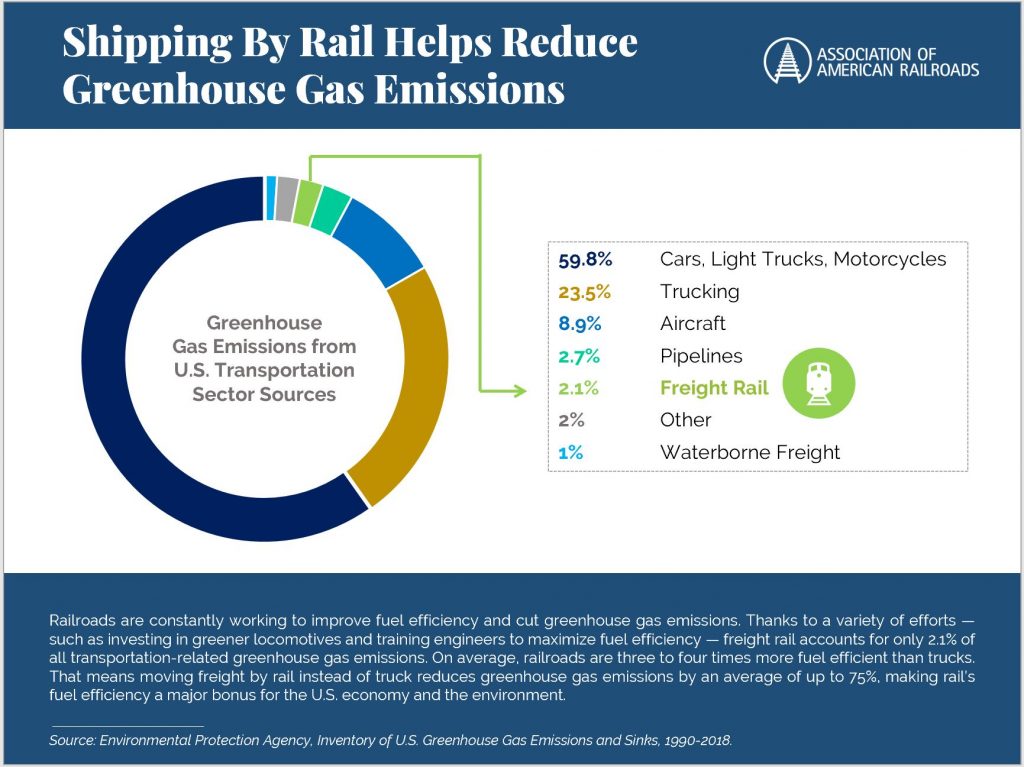

“In truth, freight rail is often an unsung transportation hero in our nation. Most of us don’t think of freight railroads unless something goes wrong, or we are inconvenienced by them. Fortunately for us, freight railroads are more efficient and safer than ever.

“In truth, freight rail is often an unsung transportation hero in our nation. Most of us don’t think of freight railroads unless something goes wrong, or we are inconvenienced by them. Fortunately for us, freight railroads are more efficient and safer than ever. “But while many of our highways, waterways, runways and other publicly funded infrastructure have been starved for cash, one mode — freight rail — has been doubling down on its private spending to steadily connect businesses and meet increasing demand. Powering investments in track, equipment and technology, rail’s spending ($25 billion annually in recent years) helps shippers move more, move it more efficiently and move it at lower cost.”

“But while many of our highways, waterways, runways and other publicly funded infrastructure have been starved for cash, one mode — freight rail — has been doubling down on its private spending to steadily connect businesses and meet increasing demand. Powering investments in track, equipment and technology, rail’s spending ($25 billion annually in recent years) helps shippers move more, move it more efficiently and move it at lower cost.” On top of this momentum, city officials

On top of this momentum, city officials

As valuable as these one-on-one meetings are in terms of educating local leaders about freight rail technological innovation, for example, the GoRail team also arranges to speak in front of larger audiences to spread the positive message about rail. March presentations included the

As valuable as these one-on-one meetings are in terms of educating local leaders about freight rail technological innovation, for example, the GoRail team also arranges to speak in front of larger audiences to spread the positive message about rail. March presentations included the