Washington, D.C. — To someone passing by, a rail yard might look like organized chaos—trains idling, tracks crisscrossing in every direction, and railcars scattered across the landscape. But behind the noise and steel is a finely tuned system built to do one thing: get railcars where they need to go, fast and safely.

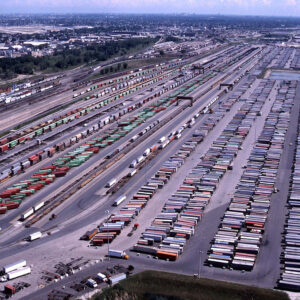

Railyards, of which there are more than 500 across the United States, are the sorting rooms of the freight rail world. Their job isn’t to store railcars—it’s to organize them. Each yard is a collection of tracks designed to receive, rearrange, and dispatch railcars based on cargo and destination. It’s a complex orchestration of timing, logistics, and mechanical innovation.

Types, Tools, and Tech

Most yards fall into two categories: flat-switching yards, where switcher locomotives manually sort railcars by pushing and pulling them across tracks; and hump yards, where railcars are rolled downhill from a small hill (the “hump”) into sorting tracks below.

A key feature in hump yards are retarders, or track-mounted brakes that grip the wheels and control each car’s speed. These were once state-of-the-art, but many hump yards have been decommissioned in recent decades due to high operating costs and changing freight patterns. Flat-switching yards are the most commonly used today.

Today’s modern rail yards also rely on tech like Radio-Frequency Identification (RFID), GPS, and yard management systems to track car locations in real time and reduce errors. In large intermodal yards, cranes and reach stackers handle container transfers, while crews coordinate via handheld radios or app-based platforms.

A System Built to Move

Rail classification yards have evolved alongside the railroads they serve. Early yards were typically squeezed into urban terminals. But by the 1950s, railroads were building larger, more efficient facilities away from congested city centers. And while some legacy yards remain, many freight carriers today are focused on streamlining: fewer yards, smarter layouts, and tech-driven efficiency.

Take CSX’s intermodal yard near Chicago: by using simulation software to redesign the layout, the company boosted processing capacity by over 15%—without expanding the physical footprint. Or consider BNSF’s Barstow International Gateway project, a $1.5 billion master-planned facility that’s reimagining freight movement with clean-energy cargo handling, streamlined intermodal transfers, and an innovative connection from port to mainline in Southern California. These success stories and innovative projects show how smart, strategic investments can unlock long-term efficiency gains in the rail network.

Why does it matter? Because every box of cereal, bolt of fabric, or case of auto parts probably passed through a rail yard at some point. These facilities may not be visible to most Americans, but they’re a critical part of the system that keeps our shelves stocked and supply chains humming.