Washington, D.C. — The Association of American Railroads (AAR) announced the new safety record, which is based on data from the Federal Railroad Administration (FRA), March 22. The news continues a trend of record-setting years for rail safety. For example, March 2017 data from the FRA shows:

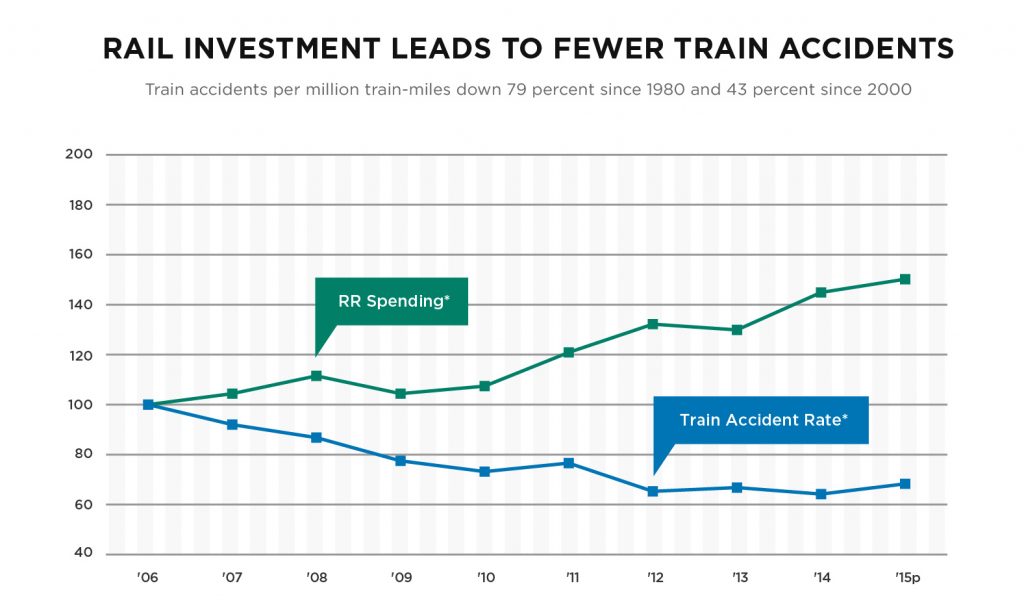

- Train accident rate is down 44 percent since 2000.

- Equipment-caused accident rate is down 34 percent since 2000.

- Track-caused accident rate is down 53 percent since 2000.

- Derailment rate is down 44 percent since 2000.

One of the key takeaways from this announcement is that safety increases can be tied to freight rail’s massive investments into the nationwide network. While railroads are the economic powerhouse that helped develop this nation, there is nothing old fashioned about rail technology. From drones to big data to mobile phone apps, railroads are innovating to improve safety.

Let’s explore five things you might not have known about rail safety.

1. Private investments correlate with increased safety

2016 not only marked the lowest train accident rate on record, but likewise the lowest derailment rate, which declined 10 percent from 2015, and the lowest track-caused accident rate. These gains are not anomalies, but examples of how steady rail investment pays safety dividends.

2016 not only marked the lowest train accident rate on record, but likewise the lowest derailment rate, which declined 10 percent from 2015, and the lowest track-caused accident rate. These gains are not anomalies, but examples of how steady rail investment pays safety dividends.

“We see clear benefits of our investments — made possible through an economic regulatory framework that allows railroads to earn the revenues needed to invest $635 billion since partial deregulation — and believe strongly in the application of new and transformative technologies,” said AAR President and CEO Edward Hamberger.

2. Railroads are on the cutting-edge of safety

Trains have come a long way since the days of the Iron Horse. State-of-the-art technologies like big data, drones, and ultrasound technology are just a few of the innovations railroads use to advance rail safety. For example, while today’s inspection technology currently makes it possible for railroads to identify 90 percent of track defects before they lead to an incident, multidimensional ultrasonic technology, currently in testing, aims to identify the remaining 10 percent of track imperfections.

https://www.youtube.com/watch?v=q5ilKF0tkrU

Big data is also helping to identify problems before they happen. Every day, rail data warehouses receive and store the vast amounts of data gathered from the wayside detectors and other monitors along the rail network. This data — hundreds of trillions of bytes — is then used to identify critical risk factors. Railroads can then issue “composite rules,” or safety protocols, that address the piece of equipment that is at risk. AAR, for instance, used big data to issue a composite rule that sets industry-wide standards for wheels to ensure their safety and integrity.

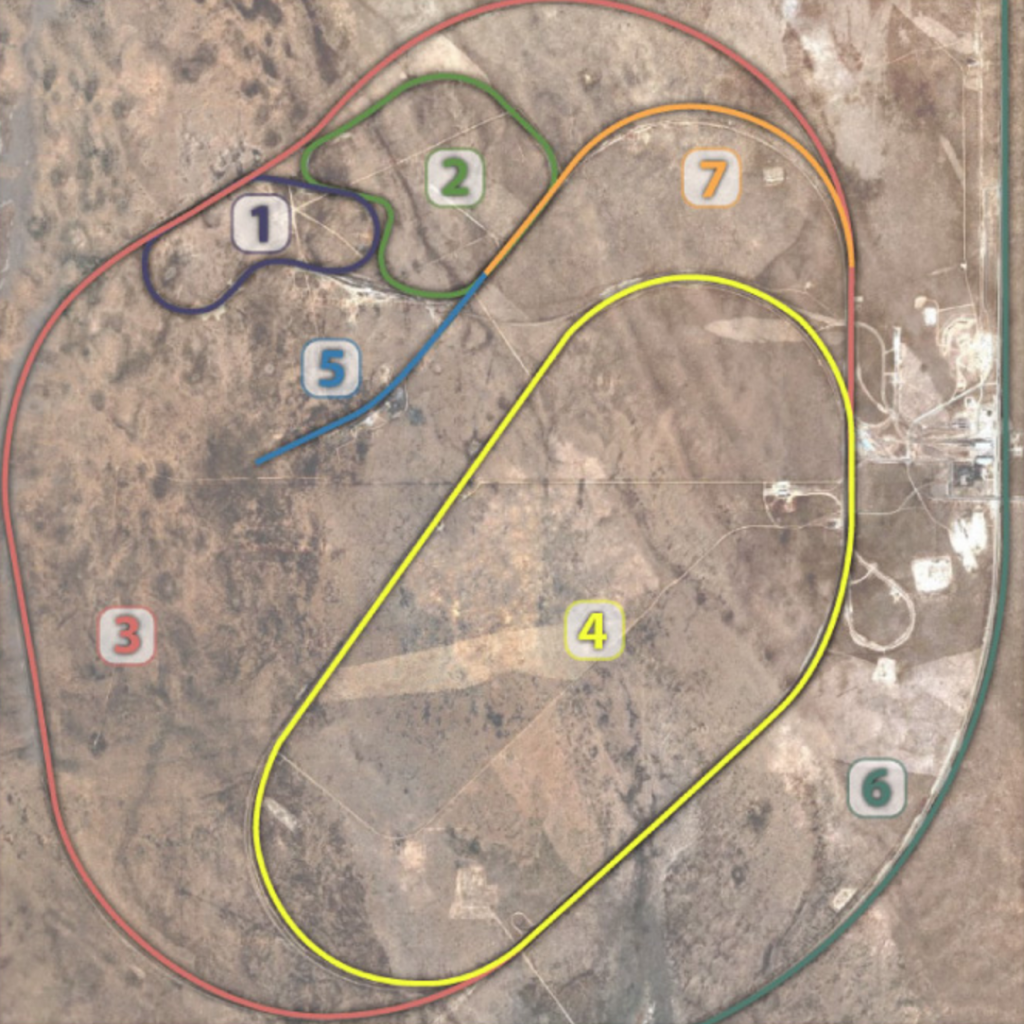

3. North American railroads partner to run the world’s leading rail research facility

In Pueblo, Colo., railroads jointly support the Transportation Technology Center, Inc., or TTCI, the world’s leading rail research and testing facility. Many of rail’s new technologies — like the world’s first laser-based rail inspection system, or on-board computer systems that analyze track geometry — are developed and tested at TTCI. Also housed at TTCI, the Security and Emergency Response Training Center (SERTC), trains thousands of first responders every year.

TTCI is also a great example of how railroads partner with the government to tackle safety. The FRA contributes about a third of its annual research budget toward projects conducted at TTCI. John Tunna, director of the FRA’s Office of Research & Development, describes the relationship: “It’s a very good example of the public-private partnership. One of the facilities at TTCI is the Positive Train Control test bed. This is a fully functional PTC system. It has both the freight implementation of PTC and Amtrak’s implementation. It has all the wayside units, the onboard units, radios and back office server. It means that people developing the system can come and test their component there and iron out the bugs before going out into railway service.”

4. There’s an app for first responders

Thousands of first responders from around the country have signed up for one of freight rail’s innovations: a mobile app called AskRail. Launched in October 2014, the app is designed to prepare responders for a rail emergency by providing immediate access to accurate, timely data about what type of hazardous materials a railcar is carrying.

Thousands of first responders from around the country have signed up for one of freight rail’s innovations: a mobile app called AskRail. Launched in October 2014, the app is designed to prepare responders for a rail emergency by providing immediate access to accurate, timely data about what type of hazardous materials a railcar is carrying.

The app, which is a collaborative effort among all North American Class I railroads, AAR, Railinc Corp. and TTCI, can only be downloaded by qualified emergency responders who have completed rail emergency training. In addition, railroads can offer the app to known emergency responders along their routes. For more information, visit: https://www.askrail.us/.

5. Positive Train Control is the largest and most complex safety system in the history of the railroad industry

In 2008, Congress mandated that railroads install Positive Train Control (PTC), a set of advanced technologies designed to automatically stop a train before certain incidents occur, across some 60,000 miles of the rail network. Because much of the PTC technology did not exist at the time, railroads and their suppliers have had to develop many of its components from scratch. Likewise, implementation requires the deployment of hundreds of thousands of technology pieces, the precise geo-mapping of tens of thousands of miles of railroad right-of-way, as well as extensive training and testing to ensure the system is interoperable.

https://www.youtube.com/watch?v=houa8Pn5nyQ

Despite the complexities and challenges of implementing PTC, freight railroads are on track to meet the deadline set out by Congress in 2015. The industry has invested upwards of $7.9 billion so far, spending about $100 million per month on continued development, testing and installation.