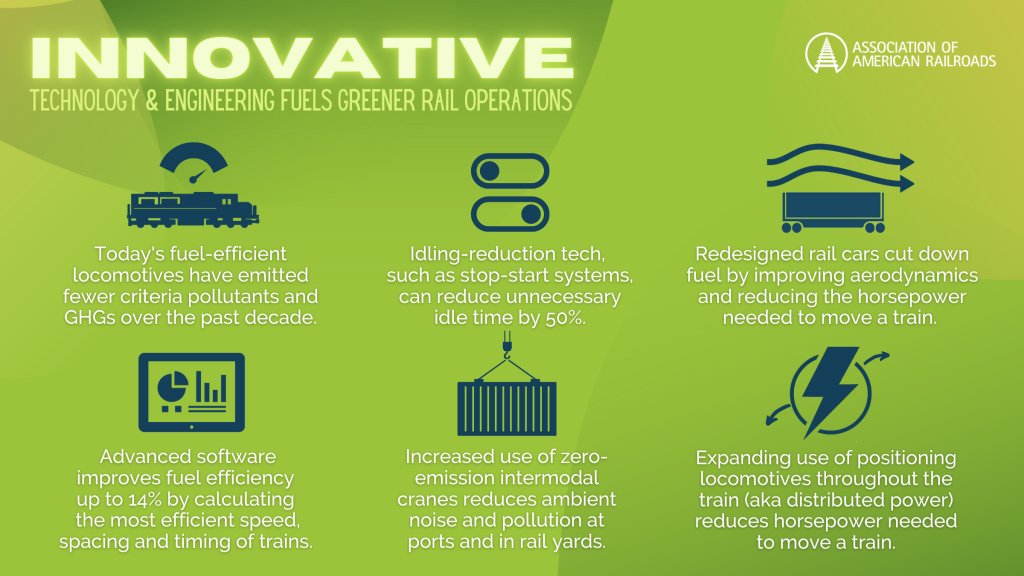

Palo Alto, CA — Freight railroads are constantly working to be even safer and more efficient – from operating practices to new technologies, advancements in railroading help keep freight railroads the safest, most affordable and most efficient way to move freight over land. While these advancements are good for companies and consumers, they’re also good for the environment.

Idling reduction technologies, for example, can reduce unnecessary idle time—when an engine is on but not in motion—by 50%. These seemingly small reductions are significant in cutting rail emissions across the network

Let’s break down how anti-idling technologies work, including the two basic types used across the U.S. locomotive fleet.

Known as a stop-start system, one type shuts the locomotive off when it idles for more than a set period of time. The locomotive engineer restarts the locomotive when it is ready for its next movement or the technology will automatically restart the locomotive when the temperature falls below a set point to prevent engine damage (as locomotive engines do not use antifreeze).

Another type of anti-idling technology uses an auxiliary power unit, which is essentially a small engine that runs to keep the locomotive’s cooling system operational and provide other vital systems with power. This allows the main locomotive engine to be shut down, significantly reducing fuel consumption and emissions.

All new locomotives and all remanufactured locomotives are required to be equipped with idle-reduction technology. However, the adoption of these systems has been much more rapid than would be expected from the gradual modernization of locomotives whose life spans can be 40-50 years.

In fact, the majority of locomotives in use today are equipped with idle reduction technology. For example, more than 99% of BNSF’s active locomotive fleet has Automatic Engine Start/Stop (AESS) technology.

These technologies can result in significant fuel and emissions savings. On average, each hour that a locomotive engine is off saves approximately four gallons of fuel. By implementing consistent idling policies and educating employees, Union Pacific reduced unproductive idling by 18% in its Rocky Mountain Service Unit. In 2019 Kansas City Southern used idle reduction technology to reduce diesel consumption by 5.3 million gallons, cutting emissions by over 60,000 tons.

Of course, this technology is just one of many used by railroads to reduce fuel consumption and operate as efficiently as possible. From intermodal facility gate pass technology and automated container inspections to trip optimizing technologies that reduce fuel consumption and ensure the correct horsepower per ton of freight optimization, railroads continue to advance.

This is good news for rail customers. Those who shipped with Norfolk Southern helped avoid 15 million metric tons of carbon emissions in 2019, the equivalent of saving 1.5 billion gallons of truck diesel.

And it is good news for the planet. In fact, CSX, CN and Canadian Pacific were all named to the Carbon Disclosure Project’s (CDP) leadership level in 2020. This puts them among the top 5% of companies scored by CDP.

Even better news is that all of the nation’s largest railroads have committed to voluntary reductions in greenhouse gas emissions intensity. Continued innovation – like rapid deployment of idle reduction technology – will help ensure railroads meet these commitments.