Washington, DC — Kicking off today, the sixth annual Infrastructure Week (May 14-21) elevates infrastructure as an issue affecting every aspect of our society. It’s also an opportune time to reflect on why the nation’s railroad connections matter — for businesses and the economy as well as drivers, consumers and the environment.

Across America, freight railroads handle over 2.2 billion tons of freight annually, hauling everything from consumer goods and food products to pulp and chemicals. These economic engines, fueled by steady investments, are often overlooked despite their vital infrastructure role across the country. Here are five reasons freight railroads are leading the infrastructure pack.

1. They’re privately owned and invest what it takes to keep the economy moving

Believe it or not, the dozens of large and small freight railroads that operate across America’s 140,000-mile rail network are nearly all privately owned. That means they’re paying their own way — a point of departure from other transportation modes that utilize publicly funded roads and waterways.

So when freight travels via rail to markets around the country (and eventually the world, in some cases), it moves along a network that is built, maintained and operated by private dollars. And like most infrastructure, the rail network requires massive spending: Class I freight railroads have collectively invested $100 billion over the last four years alone.

2. Rail is the top infrastructure student in the class

In its 2017 Infrastructure Report Card, the American Society of Civil Engineers (ASCE) awarded top marks (a “B” grade) to America’s rail system, while giving the nation’s overall infrastructure a D+. This trend continues if you compare the U.S. freight rail network to its counterparts across the world, with data showing that U.S. rail service is the world’s safest, most productive and lowest-cost.

The explanation behind these successes is simple: consistent, massive infrastructure spending. ASCE, in its report, gets at the heart of why rail companies are able to make these investments, recommending that policymakers “support a regulatory and financial environment that encourages continued private investment in the nation’s freight railroad system.” That is to say, good public policy around rail should strike a balance, allowing rail companies to earn enough to put back into the system while still protecting shippers – a principle enshrined in the Staggers Rail Act of 1980.

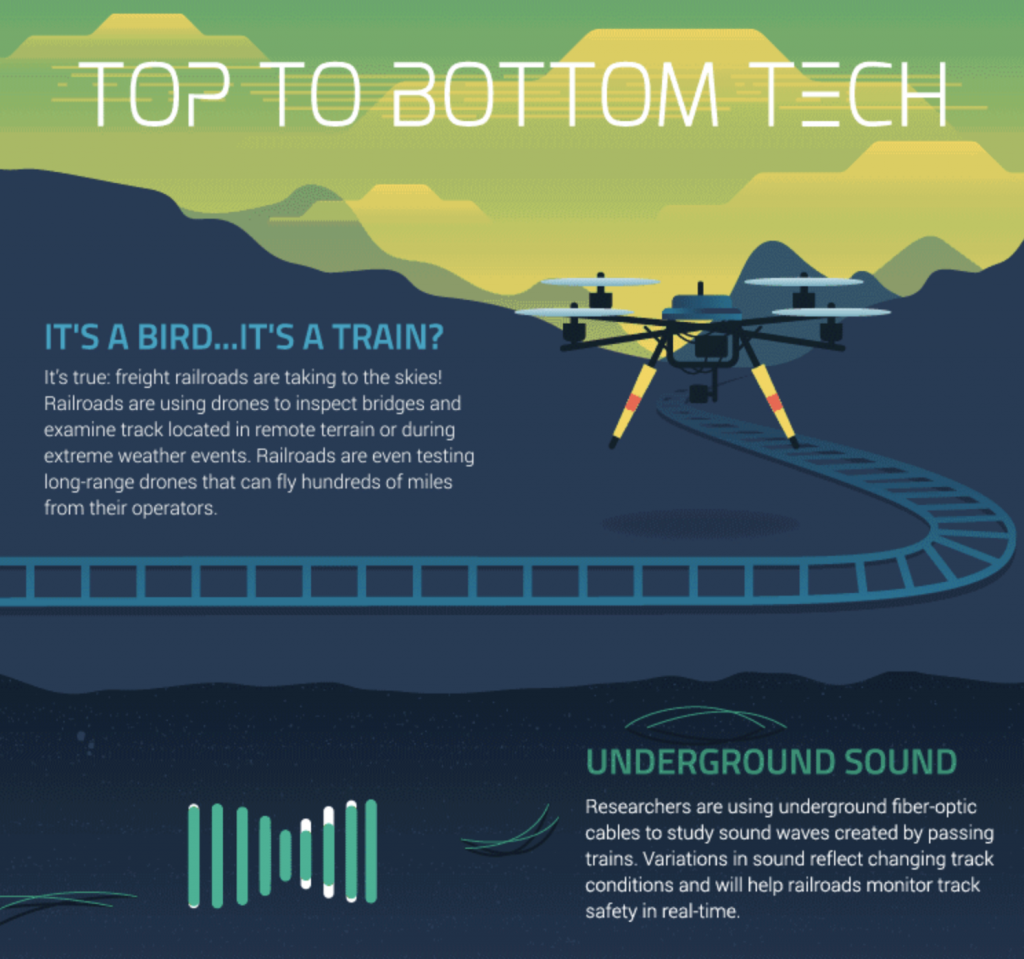

3. Iron horse innovation advances safety and efficiency

Trains have come a long way since the days of the Iron Horse. Today’s railroads rely on smart sensors that constantly monitor the health and integrity of railcars, locomotives and track, ensuring all parts of the network are at safe and optimal performance. Data and analytics are being used to spot patterns, identify maintenance needs and predict problems before they happen, which helps railroads improve safety and better serve customers.

In Pueblo, Colo., railroads jointly support the Transportation Technology Center, Inc., or TTCI, the world’s leading rail research and testing facility. Many new U.S. rail technologies — like the world’s first laser-based rail inspection system, or on-board computer systems that analyze track geometry — are developed and tested at TTCI. Also housed at TTCI, the Security and Emergency Response Training Center (SERTC), trains thousands of first responders every year, through both hands-on programs and free, web-based training for those who cannot attend in person.

Innovation in the rail industry not only makes it safer — contributing to a 28 percent decrease in the train accident rate over the past 10 years — but means customers can move more for less.

4. Rail is the greenest way to move freight over land

By design, trains have an efficiency edge on moving a lot of freight over long distances. This inherent characteristic, coupled with technological advances, means that railroads today can move a ton of freight 479 miles per gallon of fuel, double what was possible in 1980 and four times the efficiency of trucks. In fact, freight railroads’ 2017 volume was much higher than it was in 1980 while their fuel consumption fell over those 37 years.

Cleaner locomotives, engine shutdown and startup systems and advanced trip planning software also minimize rail’s carbon footprint. If just 10 percent of the freight shipped by the largest trucks instead moved by rail, annual greenhouse gas emissions in the United States would decrease by about 17 million tons—the equivalent of planting 400 million trees.

5. Trains pack an economic impact punch

Communities benefit when they have access to the nationwide rail network. Local businesses are strengthened by reliable and affordable service, bringing economic development and new jobs. Trains cut down on roadway congestion and save taxpayer dollars by moving freight over rail lines rather than publicly funded highways. They also move one-third of U.S. exports and 40 percent of intercity freight.

Research from Towson University found that, in addition to the 165,000 direct rail employees, major U.S. railroads supported approximately 1.5 million jobs across the country in 2014. Rail’s private investments also generated nearly $274 billion in annual economic activity and $33 billion in tax revenues. That means that for every dollar rail companies invest, $10 is produced across the U.S. economy.

“Senator Klobuchar serves in a crucial oversight role and we appreciate her leadership advocating for increased infrastructure investments and encouraging the use of cutting-edge technologies on the rail network” said Homan. “The privately funded and maintained freight railroad network is one of the few bright spots in America’s infrastructure network and recently received a ‘B’ grade from the American Society of Civil Engineers. It is critical that our lawmakers encourage policies that allow railroads to earn an appropriate return on their infrastructure investments so we can continue to safely expand and upgrade the network. Loram and our employees are extremely proud to provide railroads and transit systems innovative and reliable track maintenance machines and create jobs here in Minnesota.”

“Senator Klobuchar serves in a crucial oversight role and we appreciate her leadership advocating for increased infrastructure investments and encouraging the use of cutting-edge technologies on the rail network” said Homan. “The privately funded and maintained freight railroad network is one of the few bright spots in America’s infrastructure network and recently received a ‘B’ grade from the American Society of Civil Engineers. It is critical that our lawmakers encourage policies that allow railroads to earn an appropriate return on their infrastructure investments so we can continue to safely expand and upgrade the network. Loram and our employees are extremely proud to provide railroads and transit systems innovative and reliable track maintenance machines and create jobs here in Minnesota.”