Washington, DC — At first glance, a track switch might seem like just another piece of rail infrastructure. But these small, unassuming mechanisms are the backbone of a dynamic, high-capacity rail network. Without them, trains would be stuck on a single path, and freight movement as we know it would grind to a halt.

Track switches—also called turnouts or points—allow trains to transition seamlessly from one track to another, keeping traffic flowing efficiently across North America’s 140,000-mile rail network. Let’s take a closer look at what makes these mechanical workhorses tick.

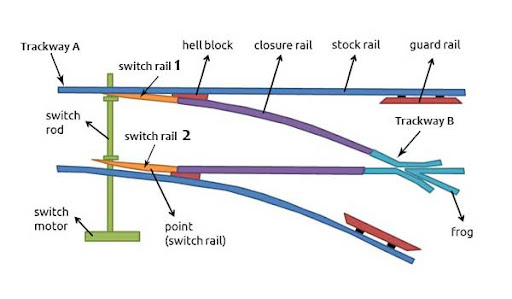

Anatomy of a Track Switch

A track switch is more than just moving rails—it’s a carefully engineered system designed for precision and safety. It has five key components that include:

- Switch Rails (Points) are the movable rails that shift position to guide a train onto a different track.

- Stock Rails are fixed rails that provide stability and form the main running track.

- The Frog is the V-shaped crossing where rails intersect, allowing train wheels to pass smoothly over gaps. The name’s origin is a bit quirky—early railroad engineers are said to have been reminded of a horse’s hoof, which features a V-shaped part called a frog. Others believe the name comes from the resemblance to a frog’s splayed legs when jumping.

- Guard Rails are smaller rails near the frog that help keep wheels aligned and prevent derailments.

- The Switch Stand, or Motor, is a device that moves the switch rails—either manually by a crew member or remotely via an electric, pneumatic, or hydraulic system.

When aligned for the main track, a train continues straight. When switched, it takes a diverging route, ensuring railroads can manage traffic with maximum efficiency.

Different Switches for Different Jobs

Not all switches are created equal. Depending on their function and location, railroads use different types of switches to handle various traffic patterns and operational needs:

- Manual vs. Powered Switches: In less-trafficked areas like rail yards, switches are often operated manually by a crew member. On mainlines, powered switches are controlled remotely from centralized dispatch centers using electric, pneumatic, or hydraulic mechanisms.

- Crossover Switches: These allow trains to move between parallel tracks. They are essential for managing multi-track corridors and facilitating efficient train movement.

- Slip Switches: Commonly found in busy rail hubs, these complex switches enable trains to cross multiple tracks at once.

- Movable-Point Frogs: Designed for high-speed rail, these switches reduce impact and wear by shifting the frog itself to provide a continuous running surface.

Modern Switching Technology

While the basic concept of a switch hasn’t changed much since the 19th century, modern technology has significantly improved their safety and efficiency. Today, many switches are integrated into advanced Positive Train Control (PTC) systems, which automatically monitor and manage switch alignment to prevent human error.

Additionally, railroads use smart sensors and predictive maintenance to detect wear, monitor temperature changes, and identify alignment issues in real time. This proactive approach helps prevent switch malfunctions, which could otherwise lead to costly delays or derailments.

In cold climates, switch heaters are deployed to prevent ice and snow buildup. These heaters, powered by gas or electricity, ensure that switches remain operational even during harsh winter conditions.

To prevent conflicting train movements, switches are often part of interlocking systems. These systems ensure that only one train can occupy a section of track at a time, reducing the risk of collisions. Early interlockings were mechanical, using gears and levers. Today, electronic interlocking relies on computerized systems for faster, more precise control.

The Unsung Heroes of Rail Efficiency

Track switches may not be as flashy as a locomotive, but they’re just as critical to the efficiency of the nation’s freight rail network. Every time a train glides from one track to another, it’s thanks to the engineering and upkeep behind these small but mighty components.

So the next time you see a train change tracks, you’ll know there’s more to it than meets the eye—just another way railroads keep freight moving and the economy on track.